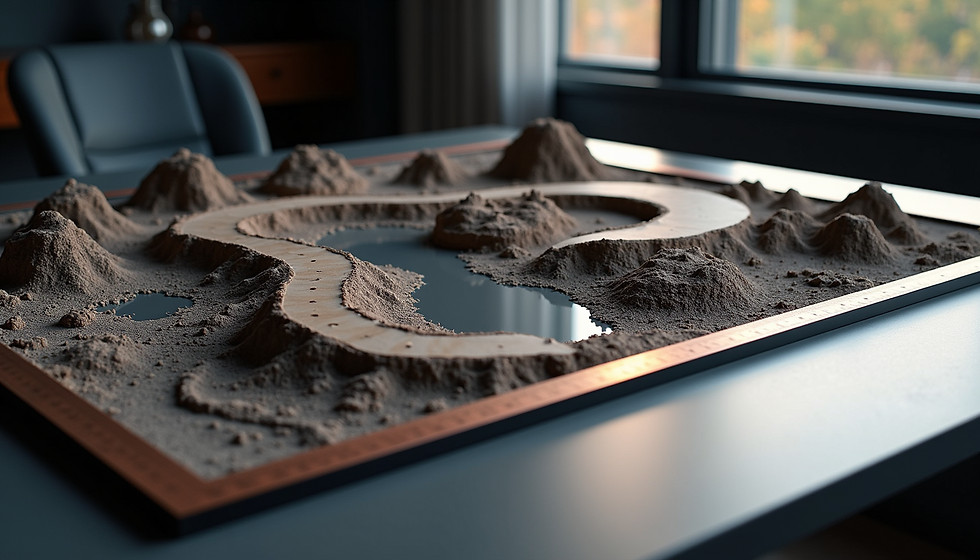

Innovative Layout Design Solutions

- Ryan Joki

- Jun 13, 2025

- 1 min read

Updated: Jul 22, 2025

We want to be engaged early in your project.

We work iteratively and closely with process engineers to establish an efficient plant layout which will form the basis of further development by specialized disciplines.

As design progresses, we facilitate communication between disciplines and incorporation of change into the overall deliverable- ensuring the project deliverables progress in line with budget and schedule.

Wholesale optimization of your facility is an integral driver of our designs as we advance them from concept to completion.

Our experienced layout designers have managed design of facilities from PEA all the way through to detailed engineering and construction; they know that a material 'improvement' in one part of the plant, or in one discipline, can rarely be de-coupled from the overall design- it often results in a 'domino effect' of change. Ensuing re-engineering and delays can ultimately push out first production and nameplate capacity by several weeks or months. In the end, delay in production could represent a net loss.

Every design decision we make is traded off against potential risk to schedule and budget to establish the true scope of change- whether it represents a net gain or loss.

In short, we seek the MinPoint- the point where there is a balance between high return and low cost/risk.